新闻动态

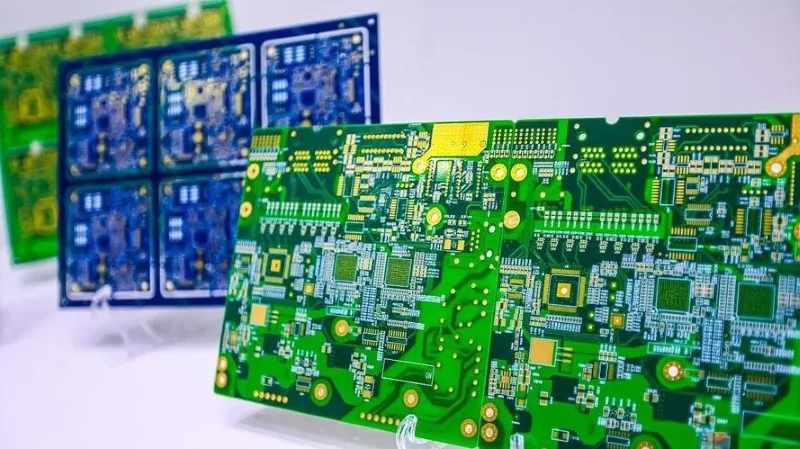

How close can components be to the PCB edge when milling depaneling?

Milling depaneling component-to-edge clearance is one of the most frequently debated topics between PCB designers, SMT engineers, and manufacturing teams. Everyone wants smaller boards, higher density, and lower cost—but routing physics does not disappear just because layouts become tighter. So, how close can components realistically be to the PCB edge when using milling depaneling? The answer is not a single number. It depends on how manufacturers define acceptable yield, as well as their process control standards and risk tolerance in real production. This article shares experience-based insights from global SMT lines, focusing on manufacturability, cost impact, and practical design–process coordination rather than theoretical limits. 🔍 Why Edge Clearance Becomes a Critical Question As PCBAs grow denser, edge space is often sacrificed first. However, insufficient clearance can lead to: Many issues are discovered too late—after tooling is already released. ⚙️ What Happens Physically During Milling Depaneling Milling depaneling removes material mechanically, which introduces: Even with a stable system, the PCB edge is not a “zero-stress zone.” Components placed too close together will feel that energy. 📏 Common Clearance Ranges Seen in Production Based on EMS and OEM field data, typical guidance looks like this: These are not hard rules—but probability curves.

Will there be burrs after cutting the PCB with a milling cutter PCB depaneling machine?

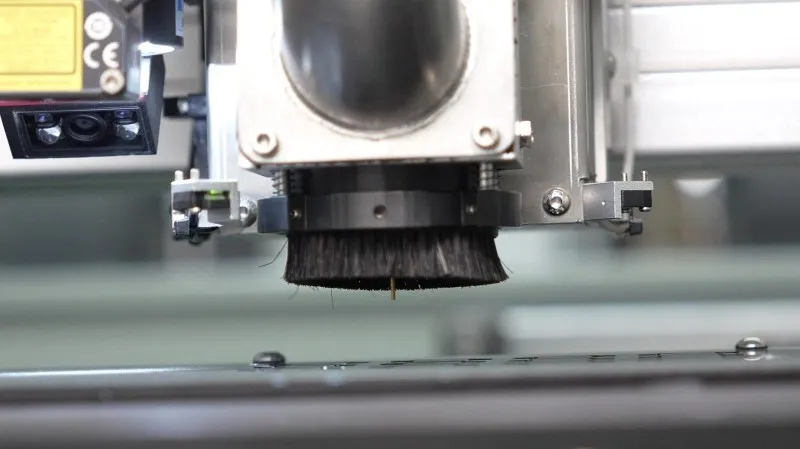

Milling cutter PCB depaneling machine burr formation is one of the most common concerns raised by process engineers—especially when boards move directly into functional testing, coating, or final assembly. Burrs may look minor, but in high-density or high-reliability electronics, they can become a real quality risk. So, will burrs appear after milling and depaneling? The realistic answer is: they can—but they are controllable. This article shares production-level insights from EMS and OEM factories, focusing on industrial quality, durability, and practical process control rather than idealized claims. 🧠 What Engineers Mean by “Burrs” in PCB Depaneling In real production, burrs typically refer to: Not all burrs are equal. Some are cosmetic, while others can interfere with connectors, housings, or conformal coating. ⚙️ Why Burrs Occur During Milling Depaneling Milling is a mechanical cutting process, so burrs are influenced by multiple interacting factors: In many cases, burrs are not a machine problem—but a process setup issue. 🪚 Tooling Choices Make a Bigger Difference Than Expected Production data shows that the tooling strategy is often the deciding factor: Factories that shifted from time-based to cut-length-based tool replacement saw a clear reduction in burr-related rework. 🧩 Panel Support and Fixturing: An Overlooked Cause Insufficient

How Much More Efficient is a Dual-Platform Milling Cutter Depaneling Machine Compared to a Single-Platform One?

Dual-platform milling cutter depaneling machine efficiency is a topic that frequently arises when SMT lines encounter throughput bottlenecks, but hesitate to add headcount or floor space. On paper, the answer seems simple: dual platforms mean higher output. In reality, the efficiency gain depends on workflow design, product mix, and how “productive time” is defined on the shop floor. This article shares practical observations from EMS and OEM factories, focusing on industrial quality, durability, and realistic return on investment—rather than idealized cycle-time calculations. 🔍 Understanding the Real Bottleneck in Single-Platform Routing In many single-platform systems, the limiting factor is not cutting speed, but non-cutting time, such as: Field data shows that the spindle may be cutting only 60–70% of total machine time. The rest is idle by necessity. ⚙️ What a Dual-Platform System Changes A dual-platform design separates cutting and handling into parallel actions: In stable production scenarios, this structural change alone often increases effective utilization. 📊 Efficiency Gains: What Production Lines Actually See Across multiple SMT environments, typical improvements reported include: The exact gain depends on panel size, routing complexity, and operator skill, but few lines see less than a one-third improvement. 🧠 User Pain Points Addressed by Dual Platforms

How Effective is the Dust Collection System of the Milling Cutter PCB Depaneling Machine?

Milling cutter PCB depaneling machine dust collection performance is often underestimated until production problems appear. Fine fiberglass dust, resin particles, and copper debris generated during routing do not just affect cleanliness—they directly influence yield, equipment lifespan, and operator safety. So how effective are modern dust collection systems in real SMT environments? This article shares practical, experience-based insights from global EMS and OEM production lines, focusing on industrial quality, durability, and long-term operational value rather than specifications alone. 🧠 Why Dust Control Matters More Than It Seems In high-density PCBA production, routing dust creates several hidden risks: Many engineers only notice dust issues after yield drops or maintenance intervals are shortened. ⚙️ How Dust Is Generated During Milling Depaneling Unlike laser or V-cut methods, milling physically removes material. This creates: An effective dust collection system must handle both heavy chips and ultra-fine particles simultaneously. 🧩 Design Factors That Define Dust Collection Efficiency Field comparisons show that dust collection performance depends less on suction power alone and more on system design: Poorly designed systems may look powerful on paper,r but lose efficiency once panels vary in thickness. 🏭 Case Insight: Medical Electronics Assembly Line A medical device manufacturer experienced unexplained contamination during

Can a Milling Cutter PCB Depaneling Machine Achieve a Cutting Accuracy of ±0.05 mm?

Milling cutter PCB depaneling machine accuracy is a recurring discussion point among process engineers working with high-value and high-density PCBAs. ±0.05 mm is often quoted in specifications—but can it be achieved consistently in real production? The short answer is yes, under defined conditions. The longer answer depends on process control, mechanical design, and expectations around repeatability versus peak performance. This article shares field-proven insights from EMS and OEM production lines, focusing on industrial quality, durability, and realistic cost–performance trade-offs. 🧭 What Does ±0.05 mm Accuracy Actually Mean in Production? In practice, cutting accuracy refers to the deviation between the programmed tool path and the final board edge. Engineers often discover that: For most SMT lines, ±0.05 mm must be evaluated as process capability, not just machine resolution. ⚙️ Key Mechanical Factors That Enable High Accuracy Achieving tight tolerances is less about marketing claims and more about mechanical fundamentals: Production audits show that machines with stronger mechanical damping maintain accuracy longer during extended shifts. 🪚 Tooling and Process Control: The Hidden Variables Even with a capable system, results degrade quickly without discipline: Several lines reached ±0.05 mm only after switching from time-based to cut-length-based tool replacement strategies. 🧩 Panel Support and

PCB Milling Depaneling Machine: Maintaining Edge Accuracy for High-Value PCBA

PCB Milling Depaneling Machine has become a cornerstone for high-value, high-density PCBAs where precision, edge integrity, and component safety are critical. Unlike V-cut or blade depaneling, milling provides controlled material removal and is especially effective for dense layouts, fragile boards, and applications demanding high reliability. This article explores practical strategies, common challenges, and field-tested solutions shared by engineers in global SMT environments. ⚙️ Understanding the Importance of Edge Accuracy For high-value PCBAs, edge accuracy is not just cosmetic—it affects: Even slight deviations or burr formation can result in micro-cracks, electrical shorts, or customer returns, highlighting the need for precise milling parameters and fixture support. 🧩 Challenge 1: Spindle Vibration and Tool Wear Field engineers frequently report that spindle vibration or dull milling bits are primary sources of edge inconsistency. Effects include: Best practices involve monitoring tool wear, calibrating spindle runout, and implementing preventive maintenance schedules. Some high-density automotive PCBA lines saw a 25% reduction in edge defects by following these steps. 🪚 Challenge 2: Panel Flex and Support Thin or large-format PCB panels can flex during milling, especially when multiple boards are processed simultaneously. Panel flex can transfer stress into populated areas, causing: Solutions include using full-surface vacuum fixtures, adaptive

.png)