Descripción

| Elemento | Especificación |

| Modelo | ZM300N |

| Effective Cutting Size (mm) | 370 × 420, 838 × 420 (two-in-one single table) |

| Funciones De Corte De | Straight, L-shape, U-shape, circular, arc, dot |

| Mesa de trabajo | Doble mesa de trabajo |

| Dust Collection Method (External Collector) | Upper or lower dust collection |

| Spindle Tool Change | Cambio automático de herramienta |

| Tool Detection | Broken tool and automatic detection |

| Safety Protection | Cortina de luz de seguridad |

| Machine Repeatability | ±0.01 mm |

| Precisión De Corte | ±0.05 mm |

| Max. La Velocidad De Movimiento | X/Y: 1000 mm/sec, Z: 500 mm/sec |

| Max. De viaje (mm) | X: 860, Y: 720, Z: 100 |

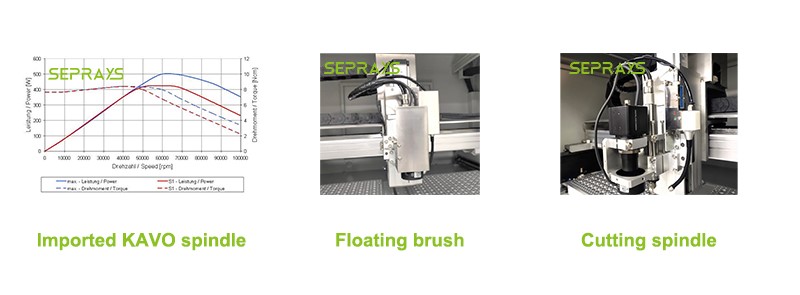

| La Velocidad Del Husillo | Max. 100,000 rpm |

| La Velocidad De Corte | 1-100 mm/s ajustable |

| Sistema Operativo | Windows 10 |

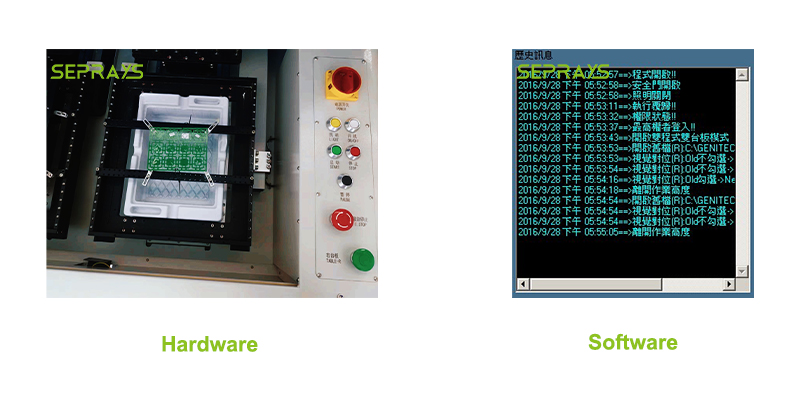

| Programming / Teaching Method | CCD color vision intuitive teaching input |

| Control Method | Precisión multi-eje del sistema de control de |

| Eje XYZ de la Unidad de | Motor servo de la CA |

| Applicable Tool Diameter | Φ0.8–Φ3.0 mm |

| Fuente De Alimentación | AC 220V, single phase, 50/60 Hz, 3.0 kW |

| Suministro De Aire | 0.6 MPa, 120 L/min |

| Machine Dimensions (W × D × H, mm) | 1360 × 1480 × 1500 |

| Peso | 750 kg |

Key Características

1. Precision Cutting

-

High-Speed Spindle: Imported precision spindle up to 100,000 rpm for exceptional cutting accuracy.

-

CCD Vision System: Automated correction ensures perfect alignment and repeatability.

-

Dedicated Jigs: Precisely fix and position the PCB to ensure cutting accuracy and prevent board movement or damage.

2. Low Stress Protection

-

Patented floating brush reduces Z-axis stress during cutting.

-

ESD-safe spindle and anti-static components prevent circuit damage.

-

Protects against solder joint cracks, lifted traces, and component failures.

3. High Productivity

-

Dual worktables for simultaneous depaneling and loading/unloading—save waiting time for loading and unloading.

-

Offline programming eliminates production line delays.

-

Using independently developed control software and motion control, it has been batch-verified by large-scale SMT factories and has strong stability. The hourly output in the same unit time is 30%+ higher than that of competitors.

4. Smart Safety & Easy Operation

-

Dual-button start, safety light curtain, explosion-proof motor, and sliding double-door design.

-

Windows 10 OS with a user-friendly interface—easy to operate and learn.

-

Customizable user accounts with access control.

5. Clean & Dust-Free

-

Upper or lower dust collection with airspeed ≥35 m/s and ≥40 m/s.

-

Negative pressure detection and an ionizing air gun for maximum dust removal.

-

Visually dust-free in SMT production.

6. Application Cases

Why Choose ZM300N?

-

30%+ higher throughput than comparable machines

-

99%+ yield rate proven in mass production

-

Global service support with fast response times

-

Designed for long-term cost efficiency with low annual maintenance costs

📩 En contacto con Nosotros para Precios y Detalles

Correo electrónico: sales@seprays.com

WhatsApp: +86-18929266433

Our PCB depaneling solution supports both PCB milling machines and routing processes, providing high-precision CNC cutting for complex PCB shapes.

.png)

Valoraciones

No hay valoraciones aún.