PCB depaneling machine selection can be a decisive factor in determining your production line’s efficiency, product yield, and overall cost structure. Many manufacturers struggle to balance machine price y cutting performance, especially when scaling up for mass production.

This article shares real industry insights, cost-analysis tips, and practical cases to help you understand the five key factors that influence both price and performance — so you can make smarter equipment investments.

⚙️ 1️⃣ Machine Type and Cutting Technology

The first element that directly impacts PCB depaneling machine price is the cutting technology used. The three main types are:

- Router (Milling) Machines: Offer high precision and flexibility for complex PCB shapes. However, they have higher tool wear and maintenance costs.

- Laser Depaneling Machines: Provide contact-free cutting with zero stress and burr-free results, ideal for delicate boards — but they come with a high initial cost.

- V-Scoring / Saw Blade Machines: Cost-effective and fast, suitable for high-throughput production lines, though less flexible for irregular shapes.

💡 Pro tip: Choosing the right type isn’t about buying the most advanced machine; it’s about matching your cutting needs, board design, and production scale.

💰 2️⃣ Material and Board Thickness Compatibility

Different PCB materials — such as FR4, aluminum, or flex boards — react differently to cutting forces.

A well-designed PCB depaneling machine should maintain consistent edge quality regardless of board thickness or copper layer density. Machines that support adaptive speed and depth control typically cost more but pay off through reduced scrap rates and improved yield.

📊 Case insight: In one customer’s SMT line, switching from a fixed-speed router to an adaptive-control model reduced material waste by 18% in the first three months.

🧠 3️⃣ Automation, Vision, and Software Integration

Modern production relies on smart automation. Machines equipped with:

- Automatic loading/unloading systems

- Vision alignment cameras

- Offline programming software

…can dramatically improve consistency and reduce labor costs.

However, these features increase the PCB depaneling machine price by 20–40%. That said, the ROI becomes evident in factories running 24/7 SMT operations, where every second counts.

🔍 Discussion point: For small and mid-size manufacturers, the right balance between automation and manual operation can make or break long-term profitability.

🧩 4️⃣ Spindle Power, Speed, and Tool Longevity

El spindle motor defines how smoothly and cleanly the machine cuts through material. High-speed spindles (60,000–100,000 RPM) deliver clean edges but consume more power and require higher-grade router bits.

That’s why router bit lifespan is often a hidden cost. A lower-priced machine with poor cooling or vibration control may wear bits faster, increasing consumable expenses over time.

⚙️ Solution insight: Investing in a stable cutting platform with real-time torque monitoring helps extend tool life by up to 25%, improving both cost-efficiency and performance stability.

🌍 5️⃣ After-Sales Support and Spare Part Availability

El price of a PCB depaneling machine also reflects the manufacturer’s service infrastructure. Machines are long-term assets — not disposable tools — and after-sales service directly affects your uptime.

Key factors to evaluate include:

- Availability of spare parts

- Remote technical support

- Response time for maintenance requests

🧾 Real example: A global EMS company reported that choosing a supplier with local service centers saved them over 48 hours of downtime per incident, compared to overseas-only support options.

🔧 Cost-Performance Balance: Finding the Sweet Spot

When comparing prices, remember that the lowest upfront cost doesn’t always equal the lowest total cost of ownership. Consider:

- Tool replacement cycles

- Power consumption

- Downtime due to maintenance

- Labor savings from automation

💬 Community question: What’s the most influential factor for your production — initial investment or long-term performance stability?

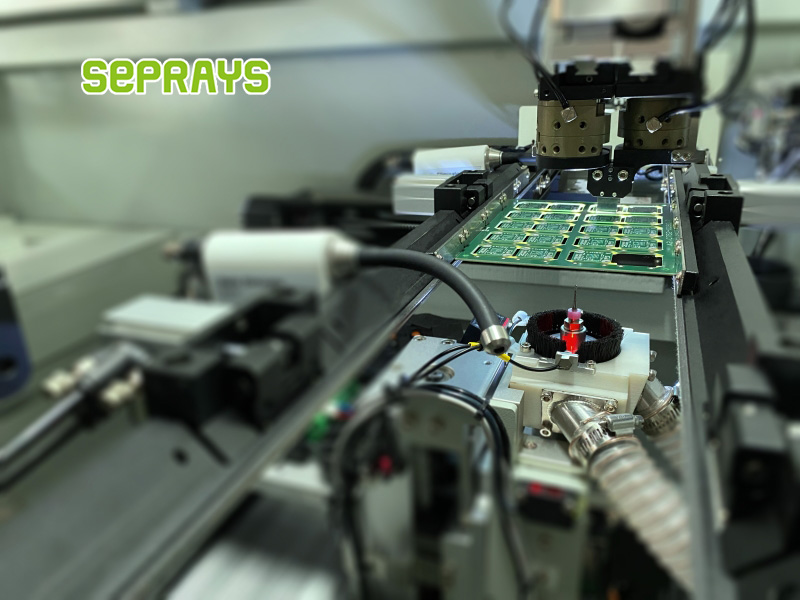

🏆 Why Choose Seprays Group?

At Seprays Group, we specialize in developing high-precision PCB depaneling machines designed to balance cost, performance, and reliability.

Our systems support router, laser, and V-cut solutions — all engineered with precision control and modular upgrades to fit your unique production needs.

Our technical team provides:

- Global installation and training

- Fast-response after-sales service

- Customizable cutting solutions

📩 If you’d like to learn more or discuss your specific PCB depaneling challenges, please feel free to contact us anytime.

📱 WhatsApp: +86 189 2926 6433

📧 E-mail: sales@seprays.com

.png)