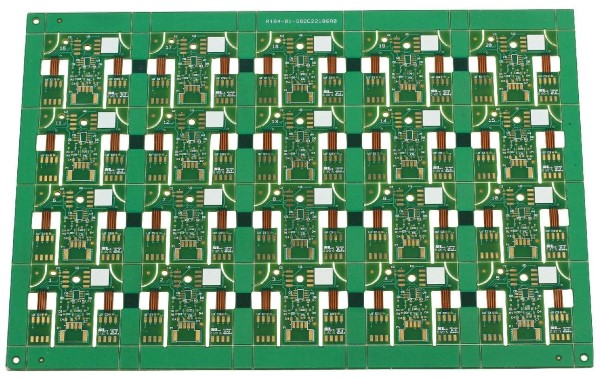

📏 Precision PCB depaneling is the key to achieving consistent quality in modern electronics manufacturing, whether producing consumer electronics, medical devices, or automotive components. A clean, stress-free cut ensures higher yields and improved reliability.

🛠 What is Precision PCB Depaneling?

Precision PCB depaneling is the process of separating individual printed circuit boards from a larger panel with minimal mechanical stress. Advanced depaneling methods—such as milling cutter machines—can achieve cuts with ±0.05 mm accuracy.

The goal is simple:

- Avoid damaging components.

- Maintain electrical integrity.

- Deliver smooth, clean edges every time.

⚙ Why Low-Stress Matters in PCB Separation

During PCB manufacturing, stress applied during separation can cause:

- Microcracks in solder joints.

- Component misalignment.

- Reduced product lifespan.

By using low-stress precision PCB depaneling equipment, manufacturers can:

- Protect delicate components.

- Reduce scrap rates.

- Improve final product quality.

💎 Mirror-Smooth Edges for Better Assembly

A mirror-smooth edge is more than just aesthetic—it helps with downstream processes such as conformal coating, enclosure fitting, and SMT assembly.

Advantages include:

- Better PCB handling during assembly.

- Improved safety for operators.

- Reduced risk of coating defects.

High-speed milling depanelers can create these smooth edges while maintaining production efficiency.

📈 Higher Yields, Lower Waste

Precision PCB depaneling directly impacts yield rates. Lower mechanical stress means fewer defects, while accurate cutting reduces waste.

Manufacturers benefit from:

- Lower material costs.

- Reduced rework and inspection time.

- Consistent quality across production batches.

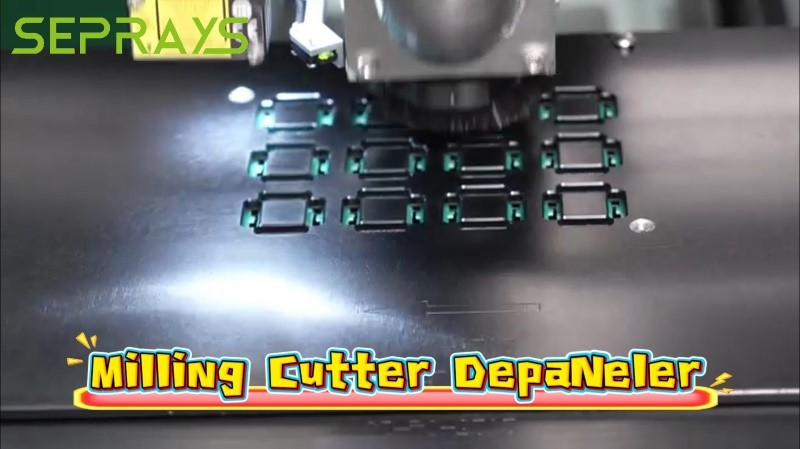

🚀 The Role of Advanced Milling Cutter Depanelers

Modern milling cutter depanelers offer:

- Down-cutting design for cleaner cuts.

- Dust extraction systems for a safer, cleaner workspace.

- Automated loading/unloading for faster cycle times.

These systems are especially useful for high-component-density boards and sensitive electronics.

🏭 Industries That Benefit Most

- Medical electronics – where reliability is critical.

- Automotive electronics – where vibration resistance matters.

- Consumer electronics – where efficiency and aesthetics are key.

- Telecommunication devices – where precision affects performance.

💡 Why Choose Seprays Group?

Since 1993, Seprays Group has been dedicated to PCB/FPC depaneling technology, providing a full range of solutions — milling cutter depanelers, laser depanelers, V-groove depanelers, punching depanelers, and automated handling systems. Our equipment is trusted by leading manufacturers, including Foxconn, Flextronics, State Grid, Luxshare, Compal, Wistron, China Electronics, Quanta, CRRC, China Aerospace, OPPO, ZTE, and Bosch, serving factories across China and worldwide.

At Seprays Group, we deliver precision depaneling solutions designed to ensure:

- ±0.05 mm cutting accuracy

- 300 μe low-stress separation

- Mirror-smooth edges for flawless assembly

- 24/7 automated operation to maximize productivity

Our machines are engineered for reliability, efficiency, and ease of use — helping you achieve higher yields and lower costs.

📧 Contact us today to discuss your production needs and discover how Seprays can help you achieve flawless PCB separation.

📞 WhatsApp: +86 189 2926 6433

📧 E-mail: sales@seprays.com

.png)