新闻动态

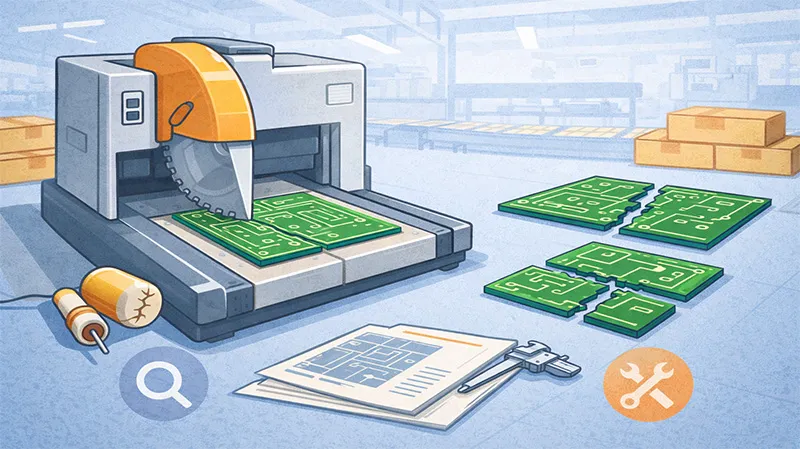

PCB V-Cut Depaneling Machine: Practical Insights from High-Volume SMT Production

PCB V-Cut Depaneling Machine usage remains widespread in high-volume SMT production, particularly where board designs are standardized, and cost efficiency is critical. Despite the rise of routing and laser solutions, V-cut depaneling continues to play an important role in consumer electronics, power modules, and industrial products. This article shares practical insights from real SMT production lines rather than promotional comparisons. 🧱 Why V-Cut Still Matters in Mass Production In high-volume environments, simplicity and predictability are often valued over flexibility. Engineers working with V-cut depaneling emphasize that when PCB layout allows sufficient edge clearance, the process can be highly efficient. Key advantages frequently mentioned: For stable product designs with long production life cycles, these benefits remain attractive. ⚠️ Stress Behavior — The Primary Engineering Concern Mechanical stress is the most discussed limitation of V-cut depaneling. In practice, the separation force applied along the groove can affect solder joints and ceramic components. Common pain points reported: As component density increases, controlling break force becomes essential. Many SMT teams adjust scoring depth, blade angle, and separation speed to reduce stress concentration. ⚙️ Machine Durability in 24/7 Production In high-output factories, machines operate continuously. Engineers often evaluate V-cut equipment based on durability rather than

PCB Depaneling Machine Supplier: Router, Laser, or Blade Solutions Compared

PCB Depaneling Machine Supplier evaluation has become more complex as global SMT lines face increasing product diversity, thinner boards, and higher reliability expectations. Rather than asking which technology is “best,” engineers now compare router, laser, and blade solutions based on stress behavior, long-term stability, and total production cost. This article summarizes real-world insights shared across SMT production environments. ⚙️ Router Depaneling — Flexibility with Mechanical Control Router systems remain widely used due to their adaptability to complex PCB outlines and mixed production. Engineers commonly highlight: Pain points include vibration management, tool wear, and dust control. In long-term operation, machine rigidity and spindle stability largely determine whether routing remains consistent over months rather than weeks. 🔥 Laser Depaneling — Precision with Thermal Considerations Laser depaneling is increasingly applied in high-density and thin PCB applications where mechanical stress must be minimized. Key advantages discussed: However, engineers also point out limitations: As a result, laser solutions are often reserved for high-value electronics rather than general-purpose SMT lines. 🪚 Blade Depaneling — Strength for Rigid Applications Blade and saw-based systems are still relevant, particularly for thick or metal-core PCBs. Typical use cases include: While durable, blade systems introduce higher mechanical force and require careful

Inline PCB Router Depaneling System in Germany: Precision and Traceability Requirements

Inline PCB Router Depaneling System in Germany is often discussed among SMT engineers because German manufacturing places exceptional emphasis on precision, documentation, and long-term reliability. In automotive, industrial control, and high-reliability electronics, depaneling is no longer a simple separation step—it is a controlled process that must meet strict quality and traceability expectations. This article summarizes lessons shared by engineers working within German SMT environments. 🏭 Precision Expectations — Beyond Nominal Accuracy In German SMT lines, accuracy is evaluated over extended production periods rather than during initial acceptance tests. Engineers frequently point out that a system capable of ±0.05 mm accuracy on day one must maintain that level after months of continuous operation. Common challenges include: As a result, inline router systems are often assessed based on structural rigidity, thermal stability, and motion control consistency rather than advertised speed. 🔍 Traceability — A Non-Negotiable Requirement Traceability plays a central role in German electronics manufacturing. Depaneling systems are expected to integrate seamlessly with MES and line control systems. Key traceability requirements discussed by engineers: Without reliable traceability, downstream quality analysis and compliance reporting become difficult, increasing operational risk. ⚙️ Inline Integration — Stability Over Throughput Inline depaneling is valued for automation, but

Automatic PCB Router Machine vs V-Cut Systems: What Global SMT Lines Prefer

The comparison between Automatic PCB Router Machines and V-Cut Systems is a topic frequently discussed among global SMT engineers, especially as PCB designs become thinner, denser, and more reliability-driven. While both technologies remain widely used, real production experience shows that the choice is rarely about speed alone—it is about long-term process stability, stress control, and total cost of ownership. 🧱 Mechanical Impact — Stress Is the First Decision Point From an engineering perspective, the core difference lies in how each method applies force to the PCB. V-cut systems rely on mechanical separation along predefined grooves. While efficient, this approach introduces bending stress that can affect: Router-based systems remove material progressively, which significantly reduces mechanical stress. Many SMT lines report fewer latent defects when routing is used for high-density or sensitive assemblies. 🎯 Accuracy and Design Flexibility One recurring pain point shared by production teams is the frequency of design changes. V-cut advantages: However, limitations appear when: Automatic routing systems offer greater flexibility, supporting complex geometries and tighter tolerances, which align better with modern PCB layouts. ⚙️ Durability and Long-Term Stability In continuous SMT environments, equipment durability often matters more than peak throughput. Engineers frequently mention: Router machines, when built with

PCB Depaneling Machine Manufacturer: What Global SMT Lines Look for Beyond Price

PCB Depaneling Machine Manufacturer selection has become a strategic decision for global SMT lines, especially as electronics move toward higher density, thinner substrates, and longer product life cycles. While price is often the primary comparison point, engineers and production managers consistently report that long-term performance, process stability, and technical support are far more important than initial cost. This article summarizes practical insights shared across SMT facilities worldwide. 🏗 Build Quality — The Foundation of Long-Term Stability One of the first aspects engineers evaluate is the mechanical structure. Lightweight frames may reduce upfront cost, but they often introduce vibration and alignment drift over time. Common concerns raised by SMT teams include: Manufacturers that prioritize rigid frames, precision linear guides, and stable spindle systems tend to deliver more consistent results under real production conditions. 🎯 Process Consistency — More Important Than Peak Performance In many factories, machines perform well during acceptance testing but exhibit different behavior during 24/7 operation. Typical pain points: Global SMT lines often favor manufacturers that focus on repeatability, motion control stability, and well-documented process parameters rather than maximum advertised speed. ⚙️ Engineering Support — A Hidden Differentiator Beyond hardware, engineering collaboration plays a critical role. Manufacturers who understand

PCB Router Depaneling Machine: What Engineers Learned About Accuracy and Stress Control

PCB Router Depaneling Machine selection has become a critical topic as PCB layouts grow denser and mechanical tolerances tighten. Across global SMT lines, engineers are no longer asking how fast a router can cut, but how consistently it maintains accuracy while minimizing mechanical stress over long production cycles. This article reflects shared lessons from real manufacturing environments rather than promotional claims. 🎯 Accuracy — Where Most Problems Begin In router-based depaneling, accuracy is not defined by a single test cut. Engineers often report that machines perform well during trials but gradually drift during continuous production. Common accuracy-related pain points include: Experienced SMT teams emphasize that stable motion control, rigid machine frames, and consistent spindle behavior matter more than nominal speed specifications. 🧩 Stress Control — The Hidden Yield Factor Mechanical stress introduced during routing is often invisible until it is revealed by functional testing or thermal cycling, at which point failures become apparent. Engineers working with fine-pitch components note that even small stress concentrations can affect solder joints near board edges. Frequently observed issues: To mitigate these risks, many factories adjust routing sequences, reduce plunge force, and prioritize even load distribution instead of aggressive cutting strategies. ⚙️ Machine Design —

.png)